Plastic Injection Molding Specialist

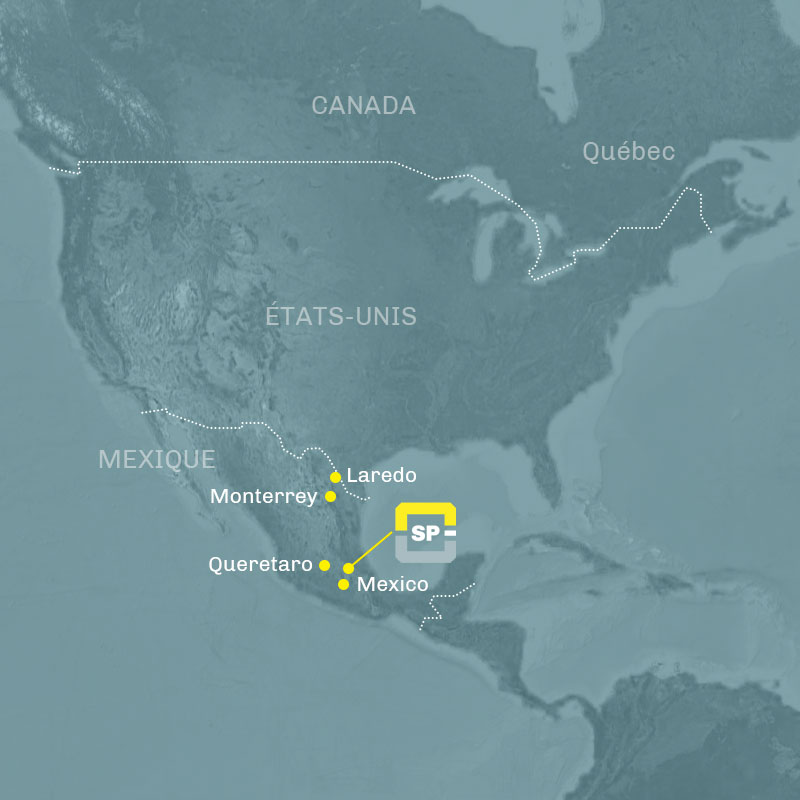

Nearshoring from Mexico to North America

Low to high-volume production – Plastic Parts Company

SP-Polynjection provides the most performance plastic injection molding service, including procurement management, logistics, inventory management, and much more, through nearshoring from Mexico.

A unique nearshoring solution

Fast manufacturing and delivery

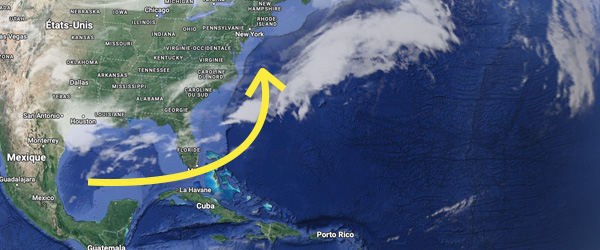

- SP-Polynjection supports companies in the plastic industry aiming to relocate a portion of their manufacturing to Mexico to be closer to their North American customers.

- Optimize your supply chain by reducing risks associated with dependence on Asia and transitioning from offshoring to nearshoring in Mexico.

- Take advantage of our high-quality service, fast production times, and affordable prices to enhance your competitiveness against your competitors.

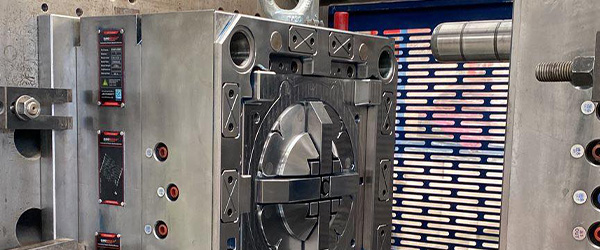

Benefit from all our expertise and state-of-the-art equipment in the field of plastic injection molding

- With over 30 years of experience in the plastics industry

- Nearshoring from Mexico to North America

- Trilingual team of engineers (French - English - Spanish), programmers, and technicians specialized in plastic injection molding

- State-of-the-art facilities and expertise

- International production standards

- Superior quality of your plastic parts

- Export to the United States and Canada with the benefits of USMCA origin rules

- 3800 m2 of floor space

- 25 injection machines ranging from 120 to 1200 tons: ENGEL, NISSEI, HAITIAN, WELLISH, AIRFA, FERRIMINO

- Equipment and robots for automating plastic injection processes

- 3PL storage and logistics service

Key sectors to outsource the manufacturing of your plastic parts

Construction

Garden articles

Consumer products

Appliances

Sports and recreation

Ground transportation

Industrial parts

Key advantages to differentiate your products from your competitors and fully satisfy your customers

Decreased production costs

Supply chain optimization

Reduced delivery times

Increased profitability

Flawless quality of parts

With Mexico being the top exporter to the United States and the third-largest trading partner of Canada in terms of goods, leverage the advantage of having a product manufactured in North America compliant with the USMCA origin rules.

High-value-added services

Are you seeking to reduce your production costs, get closer to your customers, and accelerate your delivery times? SP-Polynjection offers a unique nearshoring solution to meet your plastic injection molding projects, injection mold design, and plastic parts needs.

Injection

Outsourcing services in plastic parts production using a wide range of materials, including polyethylene (PE), polypropylene (PP), polystyrene (PS), polycarbonate, nylon, PVC, and ABS. Our capabilities span high-tech plastic injection equipment ranging from 120 to 1200 tons. Always focused on cycle optimization, consistent quality, efficiency, and customer satisfaction.

Injection molds

Comprehensive service for the design and manufacturing of molds for plastic injection. Our team of engineers collaborates closely with clients to develop custom molds that meet their exact specifications. From the initial design to the delivery of the final mold, we are committed to providing efficient and high-quality solutions to ensure the success of your plastic manufacturing project.

Design and optimization of parts

Our industrial engineers undertake the design and optimization of plastic parts to enhance functionality, efficiency, and aesthetics. Using the latest design tools and techniques, we are committed to developing innovative and customized solutions that meet the specific needs of your project, thereby optimizing performance and reducing costs.

Material selection and supplier management

Our engineering team assesses the specific needs of each project and selects the most suitable materials in terms of quality, performance, and cost. Additionally, we comprehensively manage the relationship with suppliers, ensuring the timely availability of materials necessary for production, ensuring a strong and reliable supply chain for our plastic industry clients.

Logistics and International Trade Solutions

We have the capability to store, transport, distribute 3PL, and deliver your products anywhere in North America. With an integrated computer system and highly skilled professionals, we ensure agility in all processes and guarantee efficient goods management in Mexico, the United States, and Canada.

Ready to outsource the production of your plastic parts?

Contact us

Headquarters: Mexico City – CDMX

Nearshore Plant: Parque Industrial Tizayuca, Mexico

Warehouse: Monterrey, Mexico